We are authorized representative of mass flow and pressure instrumentation to equip our customers with the tools they need to advance scientific discovery and technological development. Our devices are used in applications from aerospace and defense to research labs to environmental monitoring. To achieve this, we focus on being fast.

When we pioneered the use of laminar differential pressure flow technology, we improved on traditional thermal and differential metering to create devices which can sample every millisecond, with response times of 50 ms. That way, you get real-time data with minimal fluctuations.

If you’re building a new, automated system and need highly configured (or completely customized) mass flow or pressure controllers, you won’t be left waiting for six months. If you’re looking for a simple meter to run some tests, we likely have one we can ship right away.

Not every team has a flow expert on it, which is why we make it easy for you to get in touch with an applications engineer. They’re the ones who answer your calls by the third ring and respond to your emails within three hours. You’re able to get the information you need, fast.

we work on increasing the speed of everything we do. Displays and control buttons on our devices, multiple communication protocols, a website designed around self-help, global service centers, access to our engineering team, our online store… It’s all designed to speed up your process and the technological advancements that come with it.

Project References

Product Sales

MC–Series Mass Flow Controllers

MC–Series Mass Flow Controllers rapidly reach setpoints to maintain stable control of mass flow, volumetric flow, or pressure for 98+ gases from 0.01% to 100% of full scale.

CODA KC-Series Coriolis Mass Flow Controllers

CODA KC-Series Coriolis Mass Flow Controllers control gas or liquid flows even when the fluid composition is changing or unknown, for pressures up to 4,000 PSIA (275 barA).

MCS–Series Anti-Corrosive Mass Flow Controllers

MCS–Series Anti-Corrosive Mass Flow Controllers control flow of 128+ gases, including 32 corrosive gases.

MCQ–Series High Pressure Mass Flow Controllers

MCQ–Series High Pressure Mass Flow Controllers control flow at operating pressures up to 320 PSIA (22 barA).

Basis BC-Series Mass Flow Controllers

Basis BC-Series Mass Flow Controllers control flows in a compact, economical package for large-volume applications flowing air, Ar, CO2, N2, O2, N2O, He, or H2.

Whisper™ MCW–Series Low Pressure Drop Mass Flow Controllers

Whisper™ MCW–Series Low Pressure Drop Mass Flow Controllers control flow when there is little available system pressure, with pressure drops as low as 0.07 PSID (4.8 mbar).

Sensors (RTDs & Thermocouples)

Resistance Temperature Detectors operate through the principle of electrical resistance changes in pure metal elements which Platinum is the most widely specified RTD element type. Compared to thermocouples and thermistors, RTDs have also been known as the more expensive sensing elements because of Platinum. Platinum is popular due to its wide temperature range, accuracy and stability. RTDs are characterized by a linear positive change in resistance with respect to temperature. They exhibit the most linear signal with respect to temperature of any electronic sensing device. It should be noted, however, that RTDs would always measure ‘mean’ value of the temperature over total winding or sensitivity length.

Most RTD elements are too fragile to be used in their basic form. They’re typically built into other assemblies such as extension lead wires and encapsulated in a protective sheath. The platinum element and internal leadwires are firmly secured insulated by means of alumina insulators and MgO. This encapsulating technique immobilizes the element while protecting it from various environmental conditions and mechanical strain.

MI Inserts

Sanitary Sensor

Ambient Temp Sensor

Room Sensor

Stator Sensor

Magnetic Sensor

Thermowells

Thread Mount Thermowell

Socket/Weld Mount Thermowell

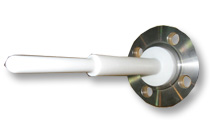

Flange Mount Thermowell

VanStone C/W Lap Joint Or Cover Flange

Ceramic Thermowell

Teflon Thermowell